1. Cane Handling & PreparationÂ

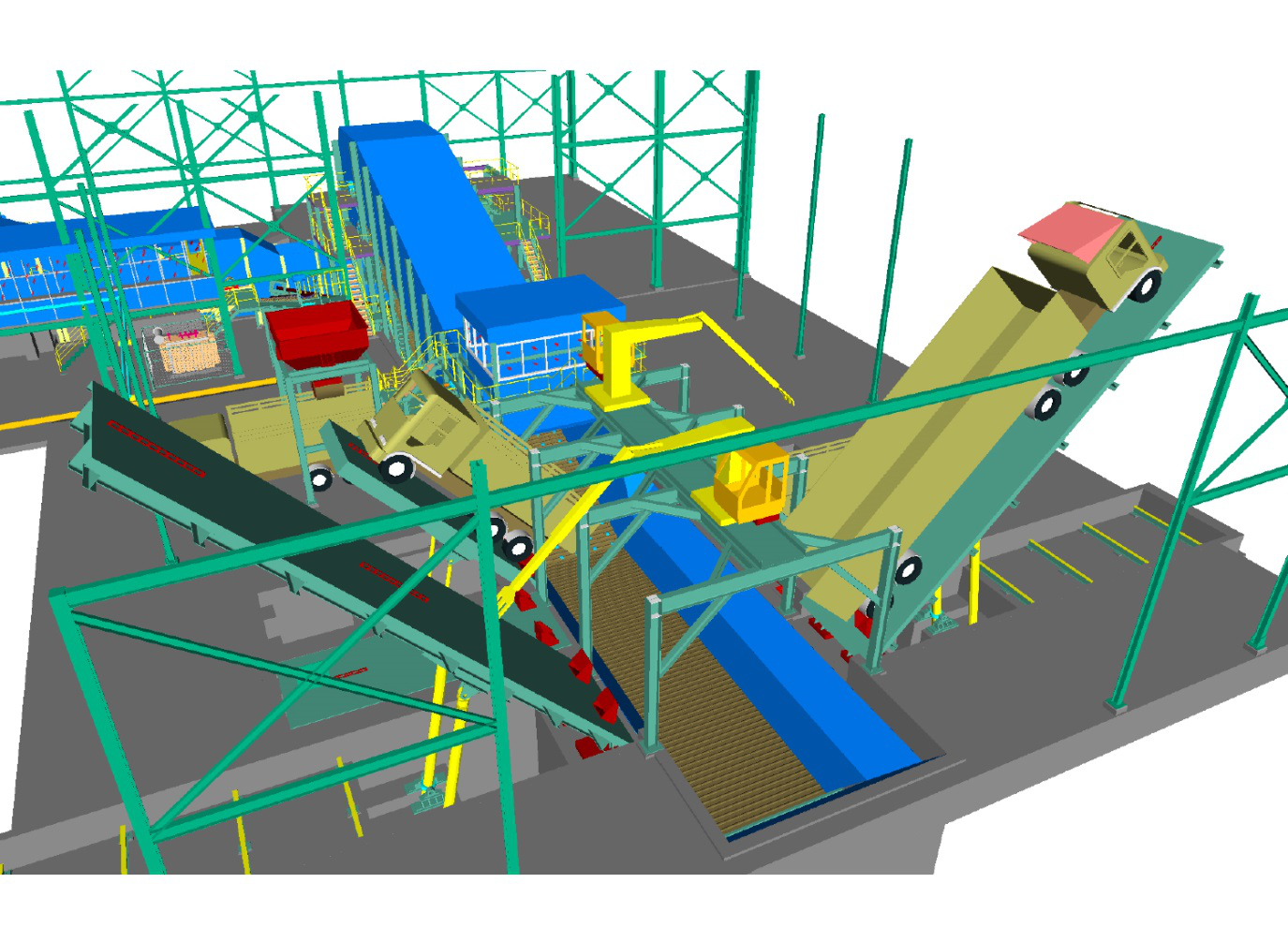

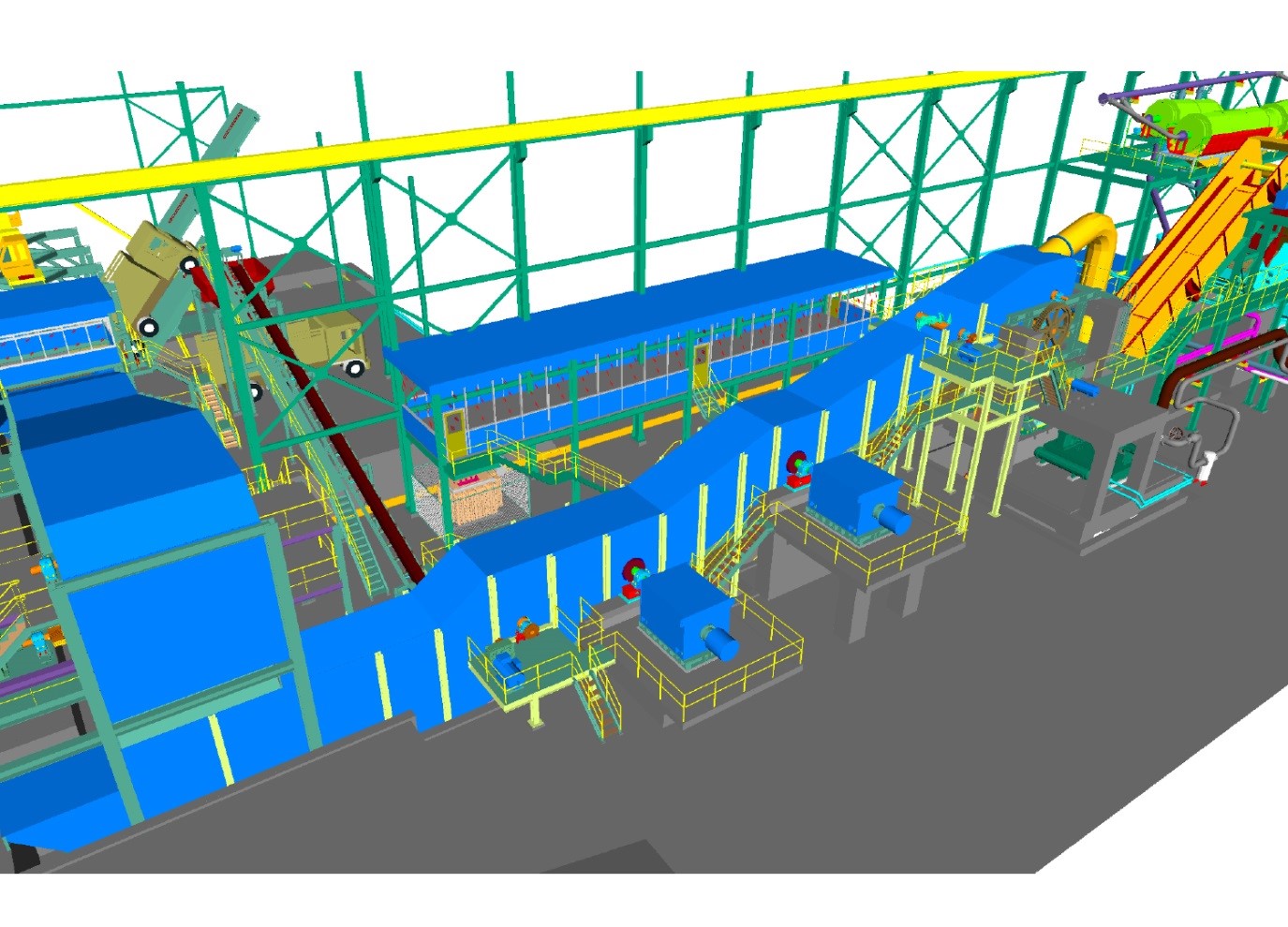

SUTECH Thailand and Indo SUTECH Sejahtera are fully equipped to supply all cane handling equipment/preparation equipment such as cane unloader, feeding table, cane kicker, cane cutter, fiberizer, chopper and cane carrier with adaptive variable drive and delivery system.

The Objectives of our design in Cane Handling & Preparation system:

- Efficient Power Consumption

- Most suitable and Effective Cane delivery to Mill Station

- Optimum achievement of Preparation Index

Cane Kicker

Cane Cutter

Electromagnet Separator

Hydraulic Truck Tippers

2. Juice Extraction (Mill Tandem and Diffuser)

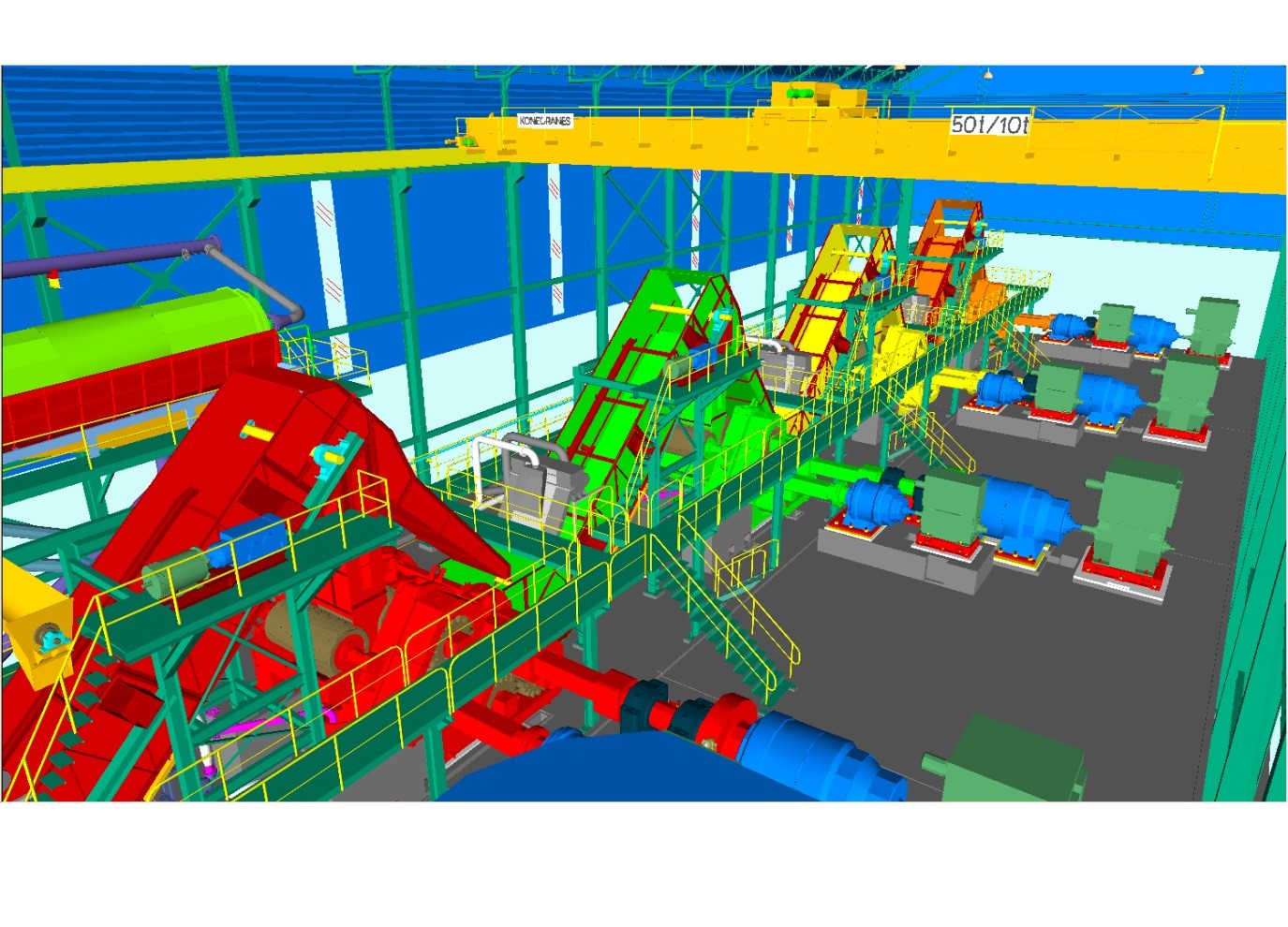

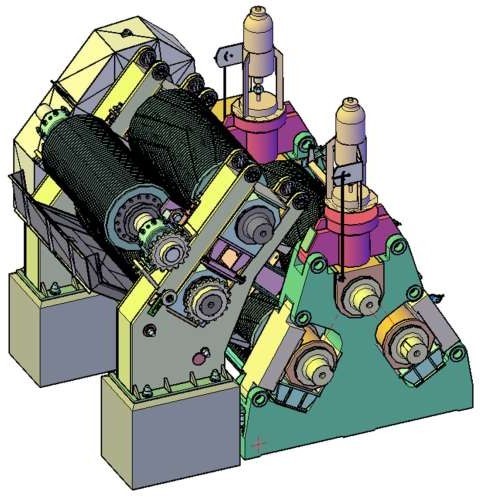

With our best consideration which involved On Farm aspect, we like to provide Juice extraction system which most suitable for client. The sugar cane milling tandem can be supplied with 3 roller, 5 roller, 6 roller mill with planetary gear drive systems, including bagasse carrier and return bagasse carrier. In 2013 Sutech signed a technology agreement with the Company Tongaat Hulett of South Africa. Under this agreement Sutech have the license for Tongaat design of Diffuser for both Cane and Bagasse applicationsSUTECH sugar mill machinery provides cost effective solution and bring state of art of technology, proven maximum efficiency that lead to high reliability

The advantages :

- Low power consumption

- Less re-absorption

- High extraction of juice with low operational cost

- Less maintenance

- High throughput

- Low bagasse moisture

- Low sugar loss in milling

- Flexibility for further expansion

Intermediate Carrier

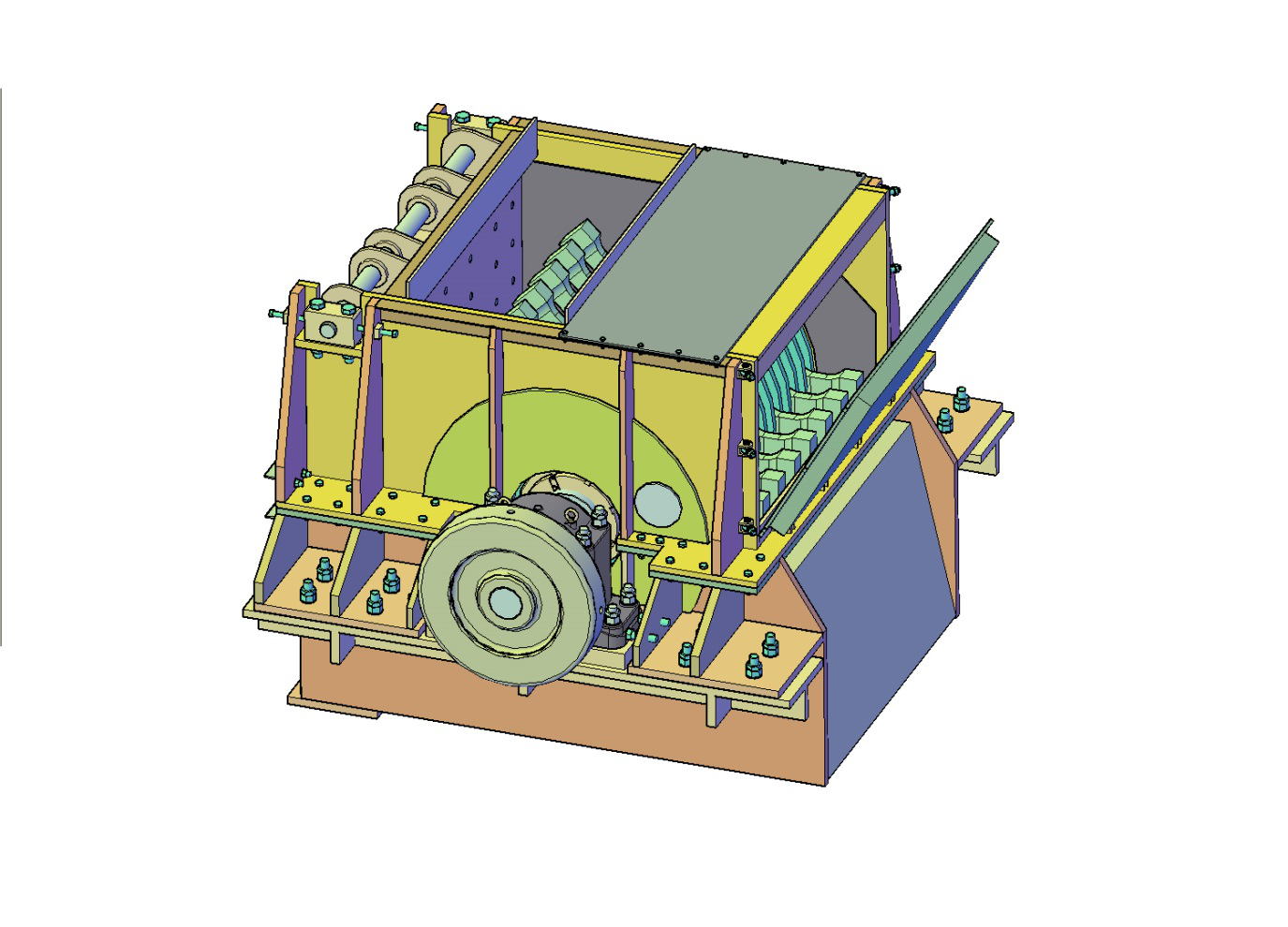

Cane Mill No. 1, 2, 3 & 4

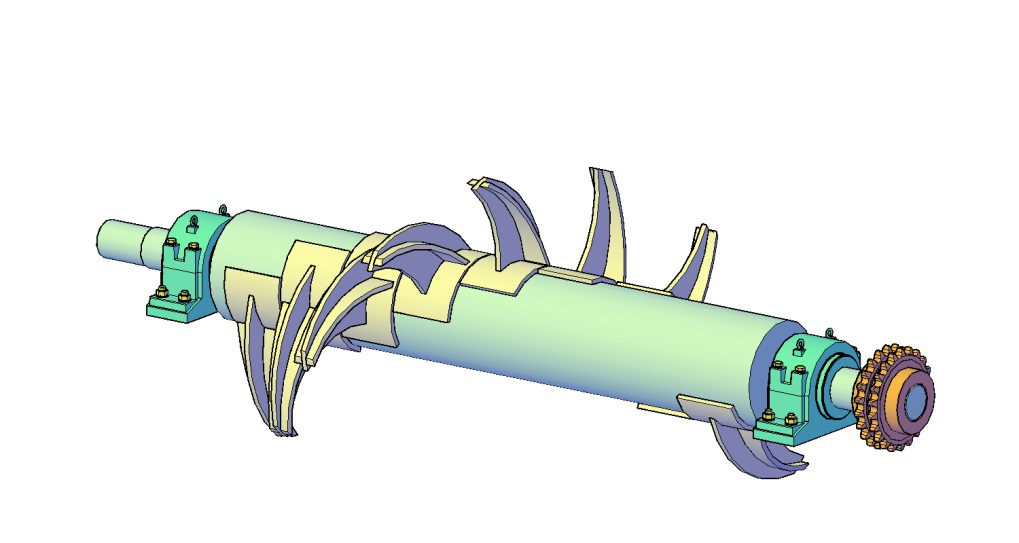

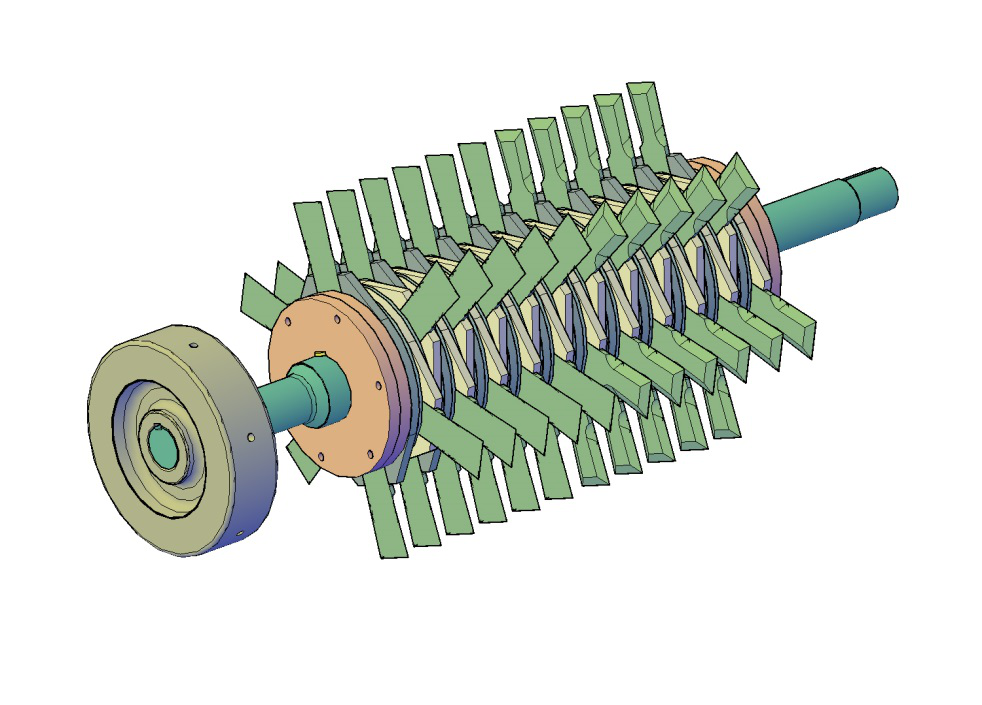

Mill Roller

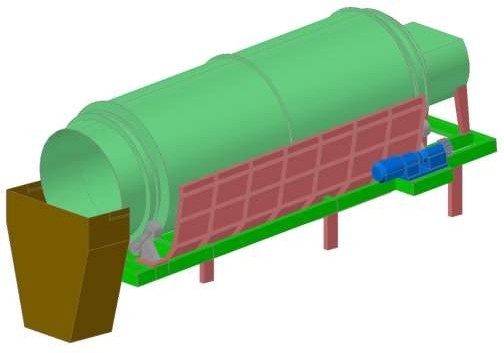

Diffuser

Rotary screen for Juice