Raw Sugar Processing:

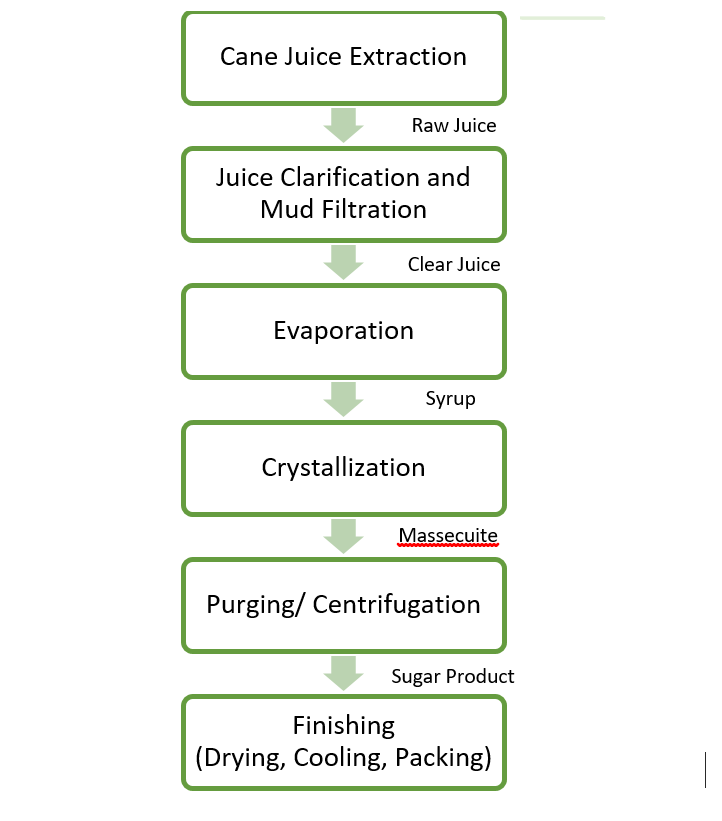

Raw sugar means sugar which is processed from sugar cane to produce brown sugar with an ICUMSA color of 600 – 1200 IU. Generally, raw sugar is used as a raw material for refined sugar processing, so the raw sugar is also known as semi-finished sugar. Raw sugar processing consists of several stages of processing after sugar cane juice is obtained from the cane extraction, then it goes through a process of clarification, evaporation, crystallization, centrifugation, and finishing.

In addition to raw sugar, in Indonesia there is also Direct White Sugar which is commonly used as sugar for public consumption. The main stage of processing direct white sugar is the same as processing raw sugar. The thing makes difference is in the purification process, raw sugar only uses lime milk to precipitate impurities in the juice or commonly called a defecation system, while in direct white sugar several other aids are used with a multilevel purification system such as defecation-sulphitation, defecation-carbonatation, and defecation-phosphoflotation so that it has a lower level of impurities and the lighter color of ICUMSA around 80-300 IU.

The following is a diagram of the raw sugar and direct white sugar processing in general:

Raw Sugar Processing Menu

Clarifier

Raw Sugar Dryer & Cooler

Rotary Vacuum Filter

Evaporator

Lime Supply & Handling System

Batch Type Vacuum Pan

Tab to Bahasa